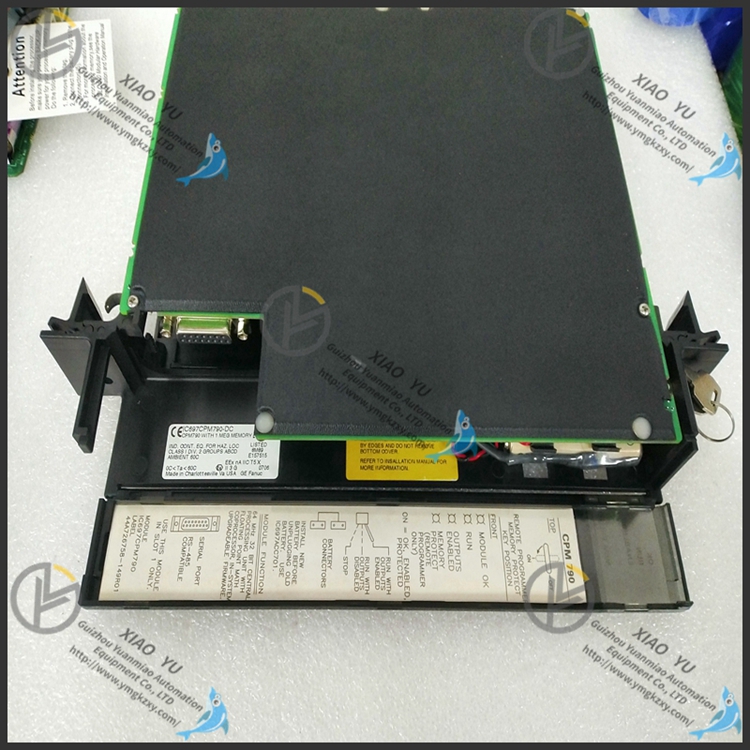

Bently 72869-02 Two-Plane Radial Vibration Monitor

-

Warranty: 365 days

Quality: Original module

Condition: New / Used

Warehouse: Spot

Delivery time: Shipped in 3 days after payment

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

-

Details

Product details

Origin:USA

Brand:bently

Product ID:72869-02

product description

Two-Plane Radial Vibration Monitor

Two-plane radial vibration monitor is an instrument used to monitor the radial vibration of

rotating machinery. It has two independent vibration sensors that monitor vertical and

horizontal vibrations respectively. This instrument can provide more comprehensive vibration

information, including amplitude, frequency, phase and other parameters, so as to help users

better understand the operating state of the machine, prevent mechanical failures, and improve

production efficiency.

Configuration:

• Monitor Range: 0 to 5 Mils

• Transducer Type: 7200 Series Prox 200 mV/Mil VT = -24 VDC

• Frequency Response: 240 to 240,000 rpm

• Alarm Timing: 1.0 Sec Delay, Latching

• Fault Protection: Timed Ok/Channel Defeat, Ok Flashing Indicator, Vert. or Horiz., Danger

Alarm, Binding Posts on Front Panel

• Danger By-Pass Switch: Not Installed

• First Out Alert and Danger: Installed

• Recorder Outputs: +4 to +20 mA ISA Standard

The operation of a biplane radial vibration monitor in an industrial environment mainly depends

on the following key aspects:

Sensor selection: First of all, you need to choose the right sensor for the specific application.

Two-plane radial vibration monitors usually use acceleration sensors to measure the vibration of

equipment. The acceleration sensor can sensitively detect the vibration of the device in the radial

direction and convert it into an electrical signal.

Signal processing: The electrical signal output by the sensor needs to be processed by the signal

processing circuit. Signal processing circuit usually includes amplification, filtering, analog-to-digital

conversion and other steps to extract useful vibration information. This information includes the

amplitude, frequency, and phase of the vibration.

Data acquisition and transmission: The processed vibration data is collected and transmitted to the

host computer or data storage device through the data acquisition module. The data acquisition module

can be an independent hardware device, or it can be integrated in the biplane radial vibration monitor.

The data transmission mode is usually wired or wireless. Select an appropriate transmission mode

according to the actual application scenario.

Display and alarm: In industrial environments, the two-plane radial vibration monitor usually has a display

unit for real-time display of the vibration of the device. The display unit can be a digital display, a chart

display or a graphical interface, which is convenient for users to view and understand. At the same time,

when abnormal vibration is detected, the monitor can trigger the alarm mechanism to inform the operator

to take corresponding measures in time.

Remote monitoring and data analysis: In modern industrial environments, dual-plane radial vibration

monitors can also be connected with remote monitoring systems to achieve remote monitoring and data

analysis. Through the remote monitoring system, the operator can understand the operating status and

vibration of the equipment in real time, analyze the historical data, predict potential faults or anomalies,

and take measures to avoid losses in advance.

To sum up, the operation of the biplane radial vibration monitor in the industrial environment requires the

cooperation and cooperation of many links. Through reasonable sensor selection, signal processing,

data acquisition and transmission, display and alarm, as well as remote monitoring and data analysis,

the real-time monitoring and effective management of equipment vibration can be realized to ensure the

smooth progress of industrial production.