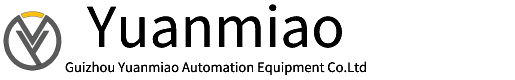

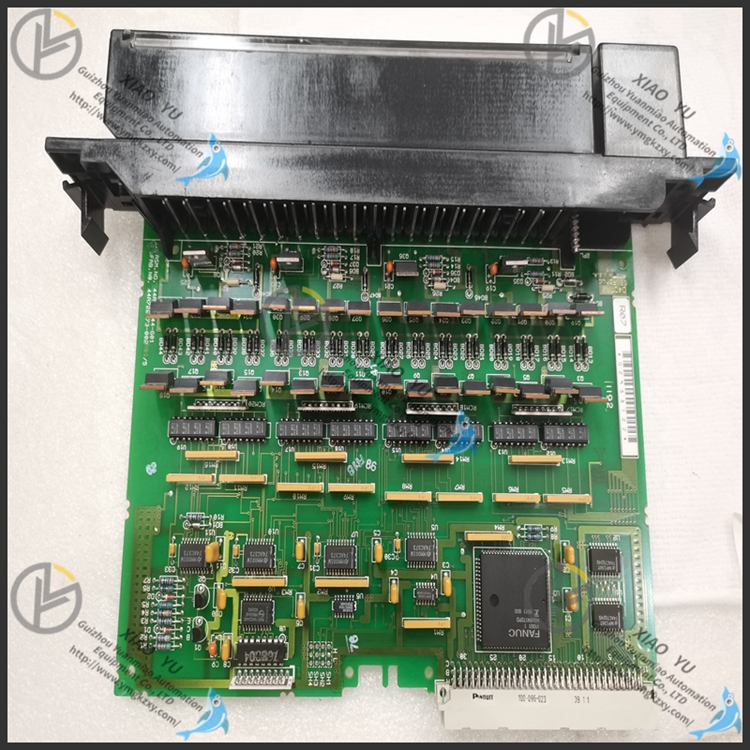

Bently 3300/95-01-07-03-00-02-03-48-02-00-03-01-00 Dual Thrust Position Monitor

-

Warranty: 365 days

Quality: Original module

Condition: New / Used

Warehouse: Spot

Delivery time: Shipped in 3 days after payment

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

-

Details

Product details

Origin:USA

Brand:bently

Product ID:3300/95-01-07-03-00-02-03-48-02-00-03-01-00

product description

The 3300/20 Dual Thrust Position Monitor provides early warning of thrust bearing failure. It continuously

measures and monitors two independent channels of shaft axial position relative to the axial clearances

within the machine.The 3300/20 Dual Thrust Position Monitor provides early warning of thrust bearing failure.

It continuously measures and monitors two independent channels of shaft axial position relative to the axial

clearances within the machine.

Configuration:

• Full-scale Range Option (01): 25-0-25 mils

• Transducer Input Option (01): 3300 or 7200 Proximitor Systems, 200 mV/mil (Ranges 01, 02, 03, 11, and 12 Only)

• Alarm Relay Option (01): Epoxy-Sealed

• Agency Approval Option (01): CSA/NRTL/C

• Safety Barrier Option (00): None

Bentley's Dual Thrust position Monitor is a device used to monitor the position of the machine's axial clearance.

It continuously measures and monitors the axial position of the shaft through two separate channels. Ideally, an

axial probe is installed to directly monitor the thrust ring, so the measurement results show the position of the

thrust bearing in relation to the thrust bearing clearance.

When using Bentley's dual thrust position monitor, it is important to note that sensor failures (clearance out of range)

can be misinterpreted by the monitor as thrust position shifts, resulting in false thrust alerts. Therefore, it is

recommended that two proximity probes be used in thrust position applications to monitor the same ring or shaft,

AND the monitor should be configured with AND voting, meaning that both sensors must simultaneously reach or

exceed their alarm set points in order to activate the monitor's alarm relay. Bentley's Dual Thrust position Monitor

is a device used to monitor the position of the machine's axial clearance. It continuously measures and monitors

the axial position of the shaft through two separate channels. Ideally, an axial probe is installed to directly monitor

the thrust ring, so the measurement results show the position of the thrust bearing in relation to the thrust bearing

clearance.

When using Bentley's dual thrust position monitor, it is important to note that sensor failures (clearance out of range)

can be misinterpreted by the monitor as thrust position shifts, resulting in false thrust alerts. Therefore, it is recommended

that two proximity probes be used in thrust position applications to monitor the same ring or shaft, AND the monitor

should be configured with AND voting, meaning that both sensors must simultaneously reach or exceed their alarm

set points in order to activate the monitor's alarm relay.