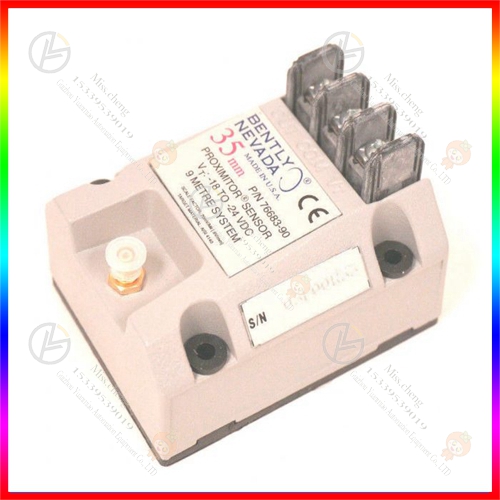

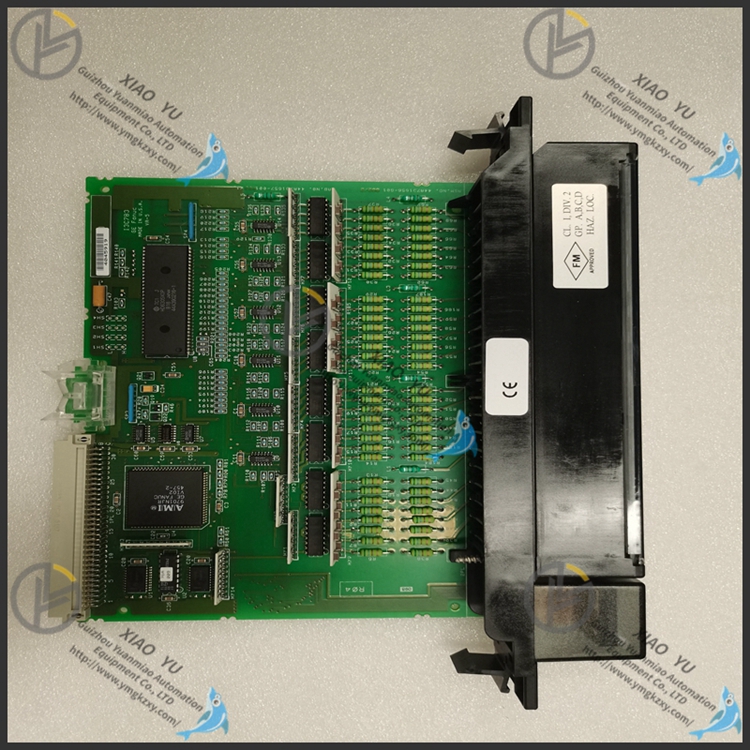

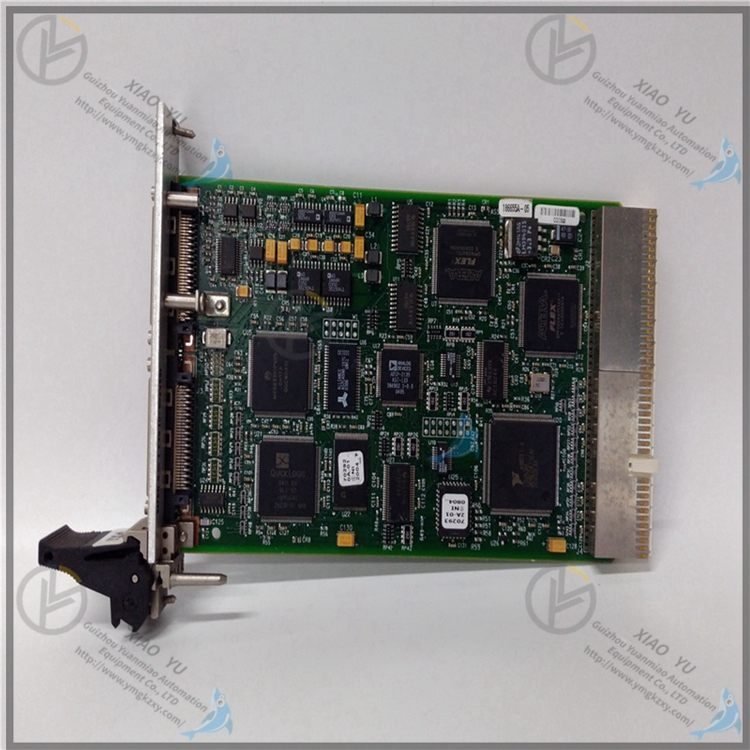

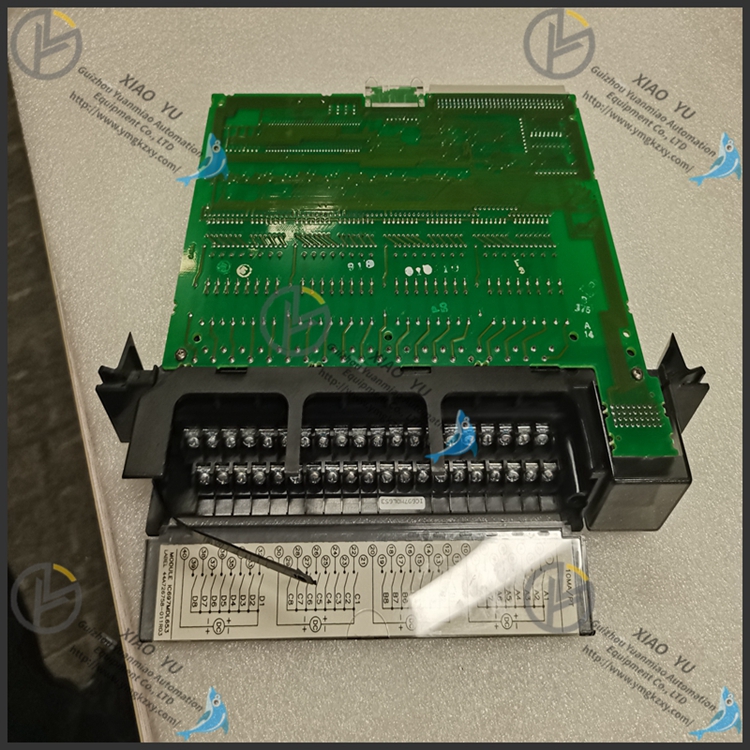

Bently 146031-01 transient data interface module

-

Warranty: 365 days

Quality: Original module

Condition: New / Used

Warehouse: Spot

Delivery time: Shipped in 3 days after payment

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

-

Details

Product details

Origin:USA

Brand:bently

Product ID:146031-01

product description

The 3500/22 is a transient data interface module with traditional static data collection

capabilities while also supporting the recording of dynamic high-resolution data. The

module is an interface to the 3500 monitoring system, which can interact with the system

configuration software and diagnostic software to collect information about the operating

status of the machine.

In 3500 racks, the TDI is located in a slot next to the power supply and can continuously

collect steady state and late state dynamic waveform data and transfer this data to the host

software over the network. Each 3500 rack requires a TDI or RIM, which always occupies slot 1.

The 3500/22 module has the following features in terms of data collection:

High-speed sampling: This module usually has a high sampling rate and is able to capture

and record short transient events, such as the shock of mechanical vibration, instantaneous

current or voltage changes in the power system, etc.

High resolution: The module can record high resolution data, such as temperature, pressure,

speed, etc., which can more accurately reflect the operating state of the machine.

Real-time monitoring: The module can monitor the running status of the machine in real time,

and transmit the data to the host software for processing and analysis.

Multiple data transmission modes: The module can transmit data through a variety of ways,

such as network, serial port, etc., so that it can adapt to different application scenarios.

Long-term recording: The module can record the running state of the machine for a long time,

so that more data can be provided for analysis and processing.

In short, the 3500/22 module has the characteristics of high-speed sampling, high resolution,

real-time monitoring, multiple data transmission methods and long-term recording, which can

better meet the needs of data acquisition and analysis in the field of industrial automation.