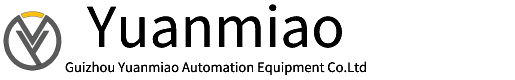

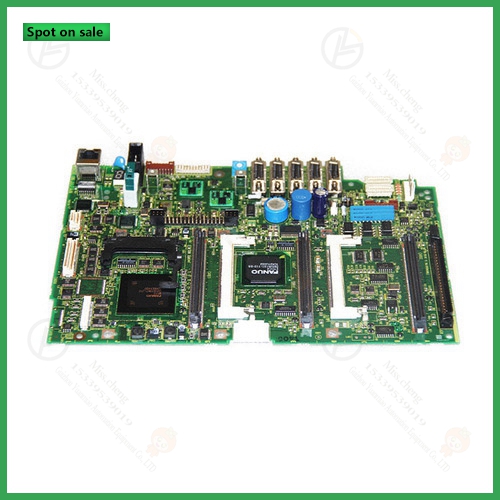

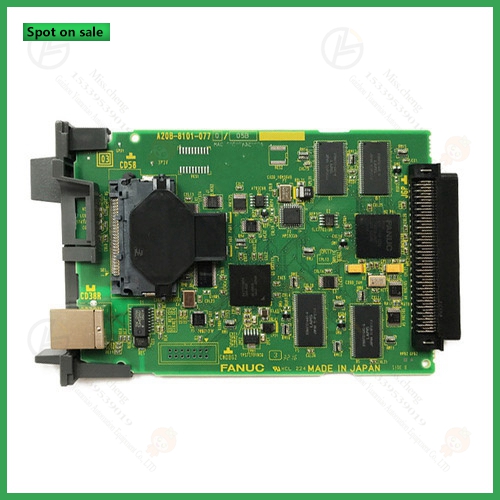

FANUC A06B-0147-B175#7076 AC servo motor

-

Warranty: 365 days

Quality: Original module

Condition: New / Used

Warehouse: Spot

Delivery time: Shipped in 3 days after payment

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

-

Details

Product details

Origin:USA

Brand:FANUC

Product ID: A06B-0147-B175#7076

product description

Fanuc servo motor refers to the AC servo motor controlled by Fanuc servo drive system,

which has the characteristics of high precision, high dynamic response and high stability,

and is widely used in CNC machine tools, industrial robots and other fields.

Fanuc servo motors are usually permanent magnet synchronous motors (PMSM) or stepper

motors and are controlled by Fanuc servo drivers. The servo drive receives the instructions

from the CNC system, and realizes the precise motion control of the machine tool or robot

through the transmission mechanism such as servo motor and reducer.

Fanuc servo motor has the following characteristics:

High precision: Fanuc servo motor adopts high precision encoder and advanced control

algorithm, which can realize high precision positioning and speed control, effectively improve

machining accuracy and surface quality.

High dynamic response: Fanuc servo motors have the characteristics of fast response, can

quickly track the instructions of the CNC system, achieve high-speed cutting and fast

positioning, improve production efficiency.

High stability: Fanuc servo motors use high-quality materials and manufacturing processes,

with high reliability and long life characteristics, to ensure long-term stable operation.

Easy integration: Fanuc servo motor is easy to integrate with FANuc CNC system, which is

convenient for users to configure and debug the system.

When using Fanuc servo motors, the following points need to be noted:

Correct installation: Install the servo motor on the CNC machine tool according to the specified

installation mode to ensure its stability and reliability.

Correct wiring: Correctly connect the power cord and signal line of the servo motor to avoid

short circuit or open circuit.

Regular maintenance: Check and maintain the servo motor regularly to ensure its normal

operation.

Pay attention to the use of the environment: pay attention to the use of the servo motor environment,

avoid high temperature, humidity, corrosion and other harsh environment.

In short, Fanuc servo motors are one of the important components to achieve high precision and

high efficiency machining. The correct use and maintenance of the servo motor can extend its

service life and improve the machining accuracy and efficiency. At the same time, it is also necessary

to pay attention to the maintenance and maintenance of the servo motor to ensure its performance

and safety. Fanuc servo motor refers to the AC servo motor controlled by Fanuc servo drive

system, which has the characteristics of high precision, high dynamic response and high stability,

and is widely used in CNC machine tools, industrial robots and other fields.

Fanuc servo motors are usually permanent magnet synchronous motors (PMSM) or stepper motors

and are controlled by Fanuc servo drivers. The servo drive receives the instructions from the CNC

system, and realizes the precise motion control of the machine tool or robot through the transmission

mechanism such as servo motor and reducer.

Fanuc servo motor has the following characteristics:

High precision: Fanuc servo motor adopts high precision encoder and advanced control algorithm,

which can realize high precision positioning and speed control, effectively improve machining accuracy

and surface quality.

High dynamic response: Fanuc servo motors have the characteristics of fast response, can quickly

track the instructions of the CNC system, achieve high-speed cutting and fast positioning, improve

production efficiency.

High stability: Fanuc servo motors use high-quality materials and manufacturing processes, with high

reliability and long life characteristics, to ensure long-term stable operation.

Easy integration: Fanuc servo motor is easy to integrate with FANuc CNC system, which is convenient

for users to configure and debug the system.

When using Fanuc servo motors, the following points need to be noted:

Correct installation: Install the servo motor on the CNC machine tool according to the specified installation

mode to ensure its stability and reliability.

Correct wiring: Correctly connect the power cord and signal line of the servo motor to avoid short circuit

or open circuit.

Regular maintenance: Check and maintain the servo motor regularly to ensure its normal operation.

Pay attention to the use of the environment: pay attention to the use of the servo motor environment,

avoid high temperature, humidity, corrosion and other harsh environment.

In short, Fanuc servo motors are one of the important components to achieve high precision and high

efficiency machining. The correct use and maintenance of the servo motor can extend its service life

and improve the machining accuracy and efficiency. At the same time, it is also necessary to pay attention

to the maintenance and maintenance of the servo motor to ensure its performance and safety.

Под серводвигателем Fanuc servo motor подразумевается серводвигатель переменного тока, контролируемый

системой сервопривода Fanuc servo drive,

, который имеет характеристики высокой точности, высокой динамической реакции и высокой стабильности,

Широко используется в станках с чпу, промышленных роботов и других областях.

Как правило, Fanuc servo motors являются постоянными магнитными синхронными двигателями (PMSM) или степпер

Двигатели и контролируются водителями сервиса Fanuc. Серво-диск получает инструкции

Из системы CNC, и реализует точный контроль движения станка или робота

Через механизм передачи, такой как серво-двигатель и редуктор.

يشير محرك فانوك سيرفو إلى محرك المؤازرة المتردد الذي يتحكم فيه نظام فانوك سيرفو

) التي تتميز بخصائص الدقة العالية والاستجابة الديناميكية العالية والثبات العالي،

)، ويستخدم على نطاق واسع في أدوات الآلات العاملة بنظام التحكم الرقمي، والروبوتات الصناعية وغيرها من المجالات.

محركات Fanuc servo عادة ما تكون محركات المغناطيس المتزامنة الدائمة (PMSM) أو السائر

ويتم التحكم فيها من قبل سائقي فانوك سيرفو. يستقبل محرك السيرفو التعليمات

من نظام التحكم عن بعد، ويدرك التحكم الدقيق في الحركة للأداة الآلية أو الروبوت

من خلال آلية النقل مثل محرك المؤازرة والمقلل.