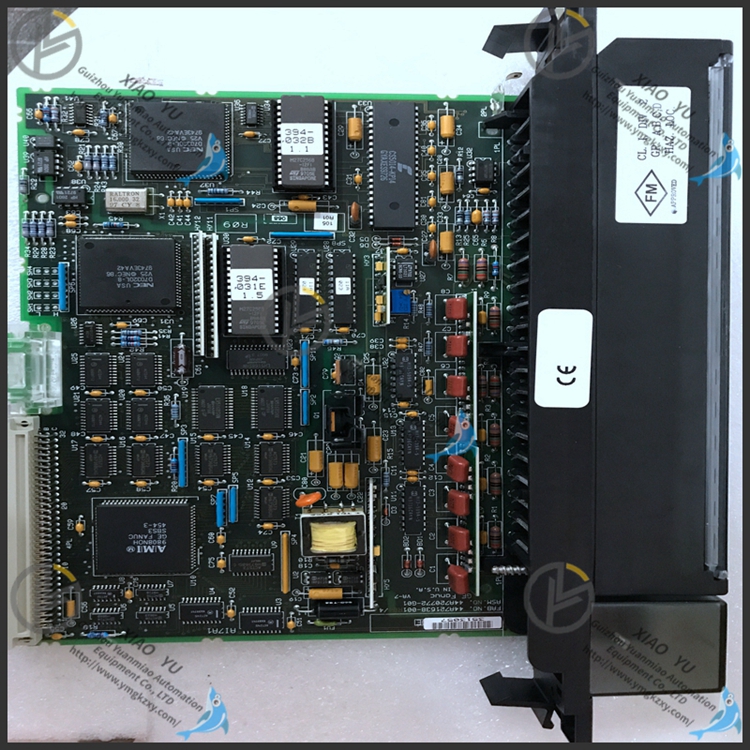

3500/77M Pressure detector

-

Warranty: 365 days

Quality: Original module

Condition: New / Used

Warehouse: Spot

Delivery time: Shipped in 3 days after payment

Mail: 3598571032@qq.com

Phone/Wechat/Whatsapp:+86 15339539190

-

Details

The Bentley 3500/77M Pressure detector is a powerful industrial monitoring device designed to monitor the

cylinder pressure of reciprocating compressors. Here is a detailed description of the product:

I. Product overview

The 3500/77M pressure detector is a four-channel monitor capable of accepting inputs from Bently Nevada

approved pressure sensors and accurately processing those signals. It continuously compares the monitored

parameter with the configured alarm setting point to activate the alarm and protect the machine. At the same

time, the detector also provides important machine operation information for operators and maintenance

personnel to help them better understand the equipment status and make timely maintenance and adjustments.

Two, the main characteristics

Four-channel design:

Each channel can adjust its input signal independently, providing various parameters called "scale values" (PPL).

Users can configure alarm and hazard setpoints for each active scale value for machine protection and fault

diagnosis.

High accuracy and reliability:

The detector uses advanced technology and algorithms to accurately measure cylinder pressure and provide

reliable monitoring data.

It has a high degree of stability and durability, and can operate stably in harsh industrial environments for a

long time.

Easy to configure and operate:

With the 3500 Framework configuration software, users can easily configure and calibrate the detector.

The graphical user interface makes the operation more intuitive and convenient.

Wide range of applications:

The 3500/77M pressure detector is widely used in chemical, oil and gas, energy generation, pharmaceutical,

food and beverage production, pulp and paper industry, water treatment facilities, manufacturing, aerospace

and transportation.

3. Technical specifications

Input signal:

Receive 1 to 4 channel signals (psia) from positive pressure third-party pressure sensors licensed by Bentley.

Output:

Provides eight PPL values related to cylinder pressure operation, including exhaust pressure, suction pressure,

maximum pressure, minimum pressure, compression ratio, etc.

Other features:

Supports remote control of indicators, RTC (real-time clock) configuration, and ping and string data transmission

between nodes.

4. Use and maintenance

Installation:

When installing the 3500/77M pressure detector, be sure to follow the installation guidelines in the product

manual to ensure proper installation and avoid damage to the device.

Commissioning and calibration:

The detector is debugged and calibrated using 3500 frame configuration software to ensure its accuracy and

reliability.

Daily maintenance:

Regular maintenance and inspection of the detector, including cleaning, tightening screws, etc., to ensure its

long-term stable operation.

If you find any problems or faults, please contact the manufacturer or professional maintenance personnel for

handling.

In summary, the Bentley 3500/77M pressure detector is a powerful and stable industrial monitoring equipment

with high precision, easy configuration and operation, and a wide range of applications. Through proper installation, commissioning and maintenance, it can ensure its long-term stable operation and provide users with reliable monitoring data. The Bentley 3500/77M Pressure detector is a powerful industrial monitoring device designed to monitor the cylinder pressure of reciprocating compressors. Here is a detailed description of the product:

I. Product overview

The 3500/77M pressure detector is a four-channel monitor capable of accepting inputs from Bently Nevada

approved pressure sensors and accurately processing those signals. It continuously compares the monitored

parameter with the configured alarm setting point to activate the alarm and protect the machine. At the same

time, the detector also provides important machine operation information for operators and maintenance

personnel to help them better understand the equipment status and make timely maintenance and adjustments.

Two, the main characteristics

Four-channel design:

Each channel can adjust its input signal independently, providing various parameters called "scale values" (PPL).

Users can configure alarm and hazard setpoints for each active scale value for machine protection and fault

diagnosis.

High accuracy and reliability:

The detector uses advanced technology and algorithms to accurately measure cylinder pressure and provide

reliable monitoring data.

It has a high degree of stability and durability, and can operate stably in harsh industrial environments for a

long time.

Easy to configure and operate:

With the 3500 Framework configuration software, users can easily configure and calibrate the detector.

The graphical user interface makes the operation more intuitive and convenient.

Wide range of applications:

The 3500/77M pressure detector is widely used in chemical, oil and gas, energy generation, pharmaceutical,

food and beverage production, pulp and paper industry, water treatment facilities, manufacturing, aerospace

and transportation.

3. Technical specifications

Input signal:

Receive 1 to 4 channel signals (psia) from positive pressure third-party pressure sensors licensed by Bentley.

Output:

Provides eight PPL values related to cylinder pressure operation, including exhaust pressure, suction pressure,

maximum pressure, minimum pressure, compression ratio, etc.

Other features:

Supports remote control of indicators, RTC (real-time clock) configuration, and ping and string data transmission

between nodes.

4. Use and maintenance

Installation:

When installing the 3500/77M pressure detector, be sure to follow the installation guidelines in the product

manual to ensure proper installation and avoid damage to the device.

Commissioning and calibration:

The detector is debugged and calibrated using 3500 frame configuration software to ensure its accuracy and

reliability.

Daily maintenance:

Regular maintenance and inspection of the detector, including cleaning, tightening screws, etc., to ensure its

long-term stable operation.

If you find any problems or faults, please contact the manufacturer or professional maintenance personnel for

handling.

In summary, the Bentley 3500/77M pressure detector is a powerful and stable industrial monitoring equipment

with high precision, easy configuration and operation, and a wide range of applications. Through proper

installation, commissioning and maintenance, it can ensure its long-term stable operation and provide users with

reliable monitoring data.

Choose Guizhou Yuanmiao. potential*

Foreign direct purchase, gen uine goods, price. Hui, after-sales warranty, model complete.

Potential inventory.

* All spare parts are guaranteed for 1 year and certified by professional testing.

* If you need to order more than 1 product, please contact us and we can offer you a discount.

* If you find other suppliers offering the same product at a lower price, we are also willing to offer you

further discounts based on their prices.

* If you have any further questions, please feel free to contact us.

Why is the price of many of our products better? Potential?

* Source procurement, reduce the intermediate link price difference

* The channel is stable, the supply of goods is more guaranteed delivery problems

* Stock spot products, after signing the contract payment, you can arrange delivery on the same day

* Ordered products, according to the quoted delivery time

Main: world famous brand PLC, DCS system accessories module. Potential supply, sufficient inventory

Foxboro: I/A Series system, FBM full series (field input/output module) sequence control, ladder

logic control, accident recall processing, digital to analog conversion, input/output signal

processing, data communication and processing.

Westinghouse: 1C31 series DCS system, CPU, OVATION system, WDPF system, WEStation system

spare parts.

Triconex (Invensys) : Redundant fault-tolerant control system, modern fault-tolerant controller

based on triple module redundancy (TMR) architecture.

EMERSON: Modules, cards, drives and other spare parts.

XYCOM: XVME series

Bently (Bentley) : 3500/3300 system.

Rockwell: ICS Systems.

ABB: PM full series DCS system, IGCT voltage inverter series, industrial robot spare parts DSQC

series, INFI 90 and so on.

Bailey: BRC series DCS system, etc.

Allen-Bradley: 1756, 1785, 1771, 1746 full series system, etc.

Yokogawa: CP series, etc.

Honeywell (Honeywell) : TK/TC/CC systems, etc.

Reliance (Ryan) : 57C series, etc.

Schneider: 140 series processors, control cards, power modules, etc.

Modicon: AS series PLC system spare parts.

Siemens (Siemens) : 6 es5 / es7414/6 es7415 / es7416 series PLC system spare parts, Siemens

MOORE, Siemens Simatic C1, Siemens numerical control system, etc.

Motorola: MVME 162, MVME 167, MVME1772, MVME177 and other series.

XYCOM: I/O, VME board, processor, etc.

GE (General Electric) : IC698/IC697 full series of PLC systems, modules, cards, drivers and other spare

parts.

Yaskawa: Servo controller, servo motor, servo driver.

Bosch Rexroth (Bosch Rexroth) : Indramat, I/O module,PLC controller, drive module, etc.

Woodward: SPC valve position controller, PEAK150 digital controller.

Price description

Price: The price of the product is displayed, and the specific transaction price may change due to the participation of the product in the activity, and may also change with the purchase quantity or the selected specifications. If the user reaches an agreement with the merchant offline, the settlement price of the offline agreement shall preva